From the 3D printing of rocket engines to launch propellants and in-space propulsion, Linde’s industrial gases play a critical role to accomplishing any space mission.

With its global multi-site rare gas production and expertise in loading systems, Linde leads the way in delivering krypton, xenon, and neon for emerging applications: from smartphone to space.

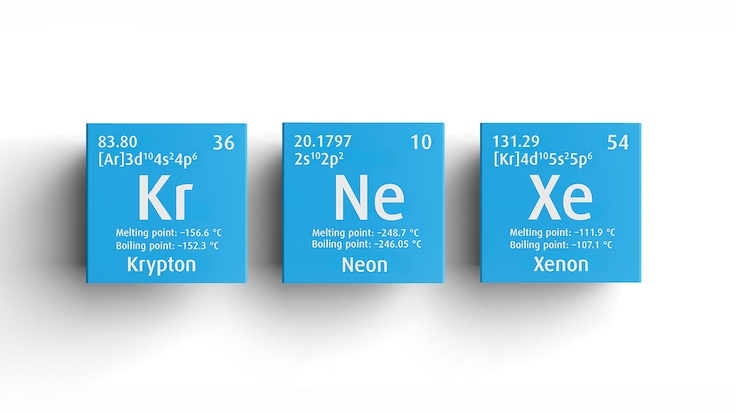

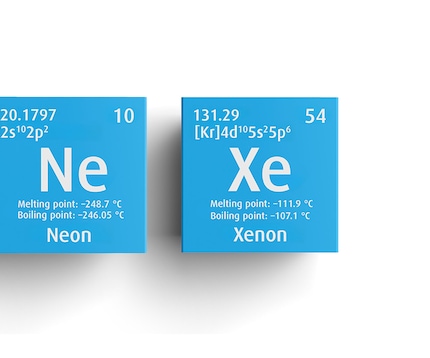

Rare gases - krypton, (Kr) xenon (Xe), and neon (Ne) - are somewhat of a paradox. They are rare in that they are found in very low concentrations in the environment - yet Linde can reliably produce and supply them in pure abundance. They are chemically known as noble gases - inert and unreactive yet therein lies the secret to their utility across a variety of novel applications. This means that, in the end, we interact with these gases anything but rarely - since they intersect with our modern lives at nearly every turn.

Consider a daily routine: You wake up and probably reach for your phone immediately to either turn off an alarm or turn on your news feed: rare gases already encountered. The properties of xenon make it the perfect media for memory chip manufacturing while the ability of neon to produce bright light makes it integral in high-resolution touchscreens. The day really starts when the display on your brand-new bean-to-cup coffee machine tells you that it's 90% done. Again, neon. You cradle your coffee as you look out the window to say hello to the world: it's the density of the krypton gas filling that is making those windows more energy efficient and sound proofed.

Maybe you get into your car and use the touch screen display there - rare gases encountered again. Maybe today is the day for your laser vision correction surgery? It's neon that forms the excimer laser. Throughout the whole day you'll be relying on internet connection: it's krypton and xenon that fuel the thousands of internet satellites currently in Low Earth Orbit (LEO).

Clearly companies increasingly rely on rare gases for their products to serve their function. And so, they need a reliable supplier of rare gases, blends and mixtures at various purities to suit whatever the application. Linde is ideally equipped to meet this rising demand, with expertise spanning sourcing and production, secure supply via an unrivalled expansive network and the specialized loading systems onsite for filling satellite tanks. But just how does something so rare get captured and delivered at sufficient volumes?

"To best understand the rarity of neon, krypton and xenon in air, imagine a populous city", explains Dr Wolfgang Dornow, Director of Rare Gases at Linde. "For every million people, only 18 would be Neon, only one person would be krypton and as for xenon, you'd only find one person in every 10 million". Naturally, this means that it takes huge volumes of air to produce small volumes of rare gases.

While the production process for Krypton and Xenon differs from that of Neon, it always starts with the Air Separation Unit (ASU): "We need ASUs with an air intake capacity of 150,000 cubic meters per hour at a minimum!" says Dornow. For krypton and xenon, the first air separation process stage extracts the gases from air and enriches them by x1500. "Our one in a million krypton person is now 1500 people and our one in ten million xenon person is now roughly 170." At this stage, the gases are still in a mixture with oxygen.

The next stage is about producing a pure krypton (92%) and xenon (8%) mixture. "This takes place in a dedicated rare gas column at the ASU of which Linde has more than 70 globally," explains Dornow. In a third and final stage, the two gases are separated from each other in a dedicated purification plant. The case of Neon is comparatively simpler. "We start with 18 parts per million (ppm) neon and after just one ASU processing stage we can reach a 50% neon mixture," explains Dornow. The neon is then separated in a second stage - again, in a dedicated purification plant.

Dornow is quick to point out that the volumes of these gases produced at each ASU are very small: "This is why a dense network of ASUs is vital for producing the gases in an economically viable way. One plant will never be enough." Economies of scale dictate that ASUs are never built for rare gas production alone. This means that customers who want rare gas supply rely on an existing network of oxygen-producing plants and a regional supply chain. "This is how Linde is able to meet demand and stay customer-centric in our supply," adds Dornow.

Some customers require the purest of pure rare gases - none more so than the aerospace industry. xenon and krypton, for example, are used for ion thrust propulsion - to transfer satellites from the rocket to their final orbits and to keep them there, resisting the pull of the Earth's gravity. In ion thrusters the rare gas is ionized, and the resulting ions accelerated by an electric field. In Hall Effect thrusters an additional magnetic field is used to produce an ion beam which propels the satellite. And with more satellites being sent into space than ever before, the demand for xenon and krypton is also heading skyward.

"We have purification plants and flexible supply chains in all three major markets - US, Europe and Asia," says Dornow. These plants can produce compressed xenon and krypton even above the standard purity of 99.999% - referred to as 5.0.

Moreover, Linde's leading-edge technology and delivery expertise means its innovative loading systems - i.e. filling the satellite from cylinders of compressed gas - are also part of its strong offering. As Dornow puts it: "Without this, it would be like the last mile problem of rare gases travel!"

From the 3D printing of rocket engines to launch propellants and in-space propulsion, Linde’s industrial gases play a critical role to accomplishing any space mission.

Linde has a vast network of production, blending and purification facilities geared towards security of supply spanning all rare gases, mixtures, purities and supply modes