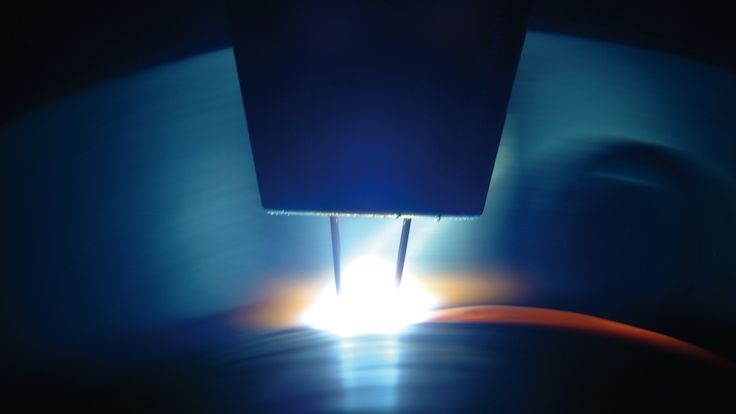

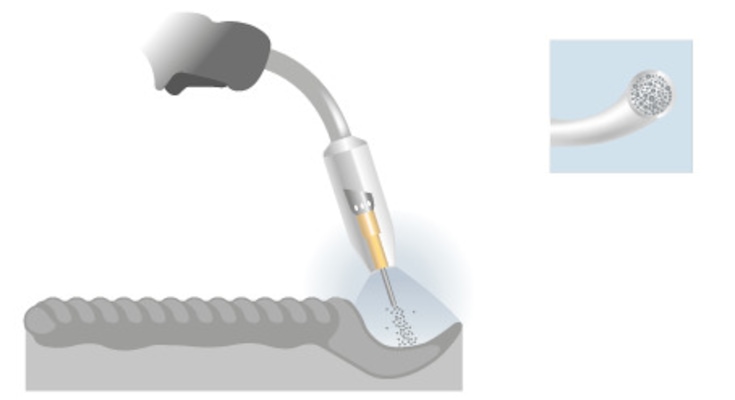

Discover how our tailored GMAW (MAG/MIG) welding gases and gas mixes can help you meet your job expectations

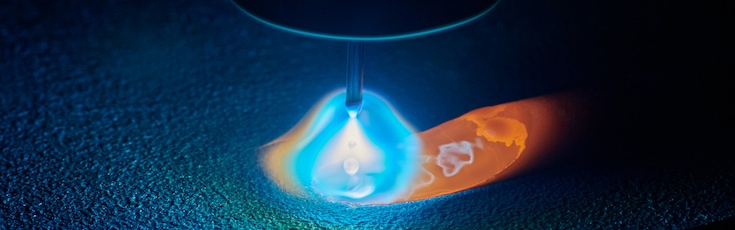

There is no single gas composition that can satisfy the diversity of physical and metallurgical challenges in arc welding, especially when you consider that gas-shielded arc welding spans four different (main) processes (GMAW , FCAW, TIG/plasma and root backing) and a virtually unlimited number of metallic alloys. So it helps to start out by understanding the physical impact of a welding gas on your process and - ultimately - on your welding outcome.

Here at Linde, we have never limited the role of our welding gas products just to "shielding" against ambient air. If we did, a simple molecule like carbon dioxide would work on all materials and for all processes. But this is not the case in industrial practice. Understanding how single gas components act in the arc and the welding zone enables us to consider all capabilities of a welding gas beyond shielding and to leverage these to the benefit of our customers.

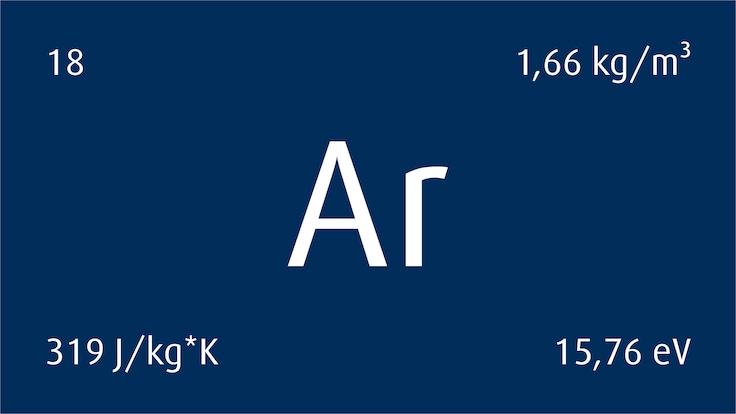

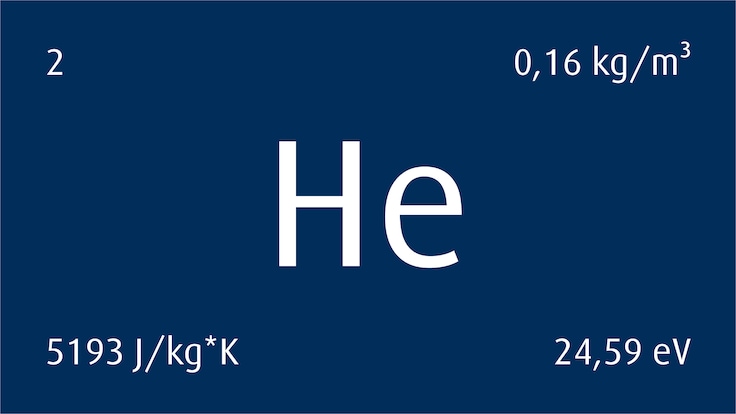

This is the base component for most blends. It is often referred to as a "noble" gas as it is chemically inert so it does not react with hot metals at any temperature - neither in the arc nor in the molten pool.

This is also an inert gas or inert component in a gas blend. It does not react metallurgically but can change the energy balance and heat transfer in the welding arc. Argon can be substituted partially or completely by helium without impacting the chemical reactivity of the blend.

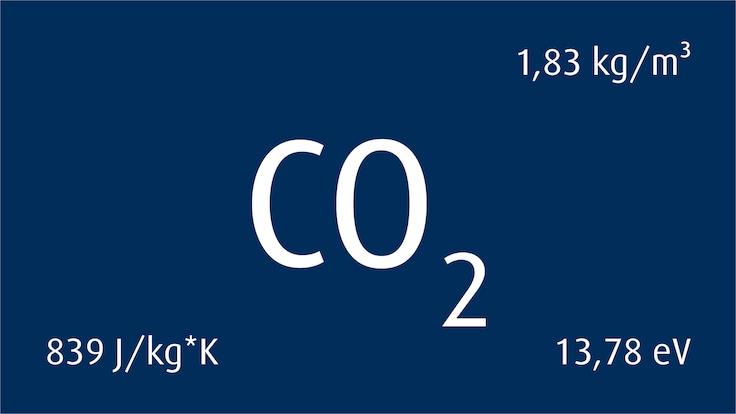

This gas decomposes with multiple interim products in the arc and is considered a reactive component in a blend. While dissociation and recombination of CO2 is generally regarded as being beneficial for heat transfer to the welded component, excessive reactivity has certain downsides. Oxidation of molten or hot metallic surfaces is inevitable, so welders have to carefully select the percentage share of this gas depending on their material and process compatibility parameters. Certain alloys can even be subject to carbon pick-up (carburization). This undesired reaction also limits the optimum CO2 content in a welding gas mix. To cover this wide spectrum, our gases portfolio extends from mixes with 0.05% CO2 content to pure CO2.

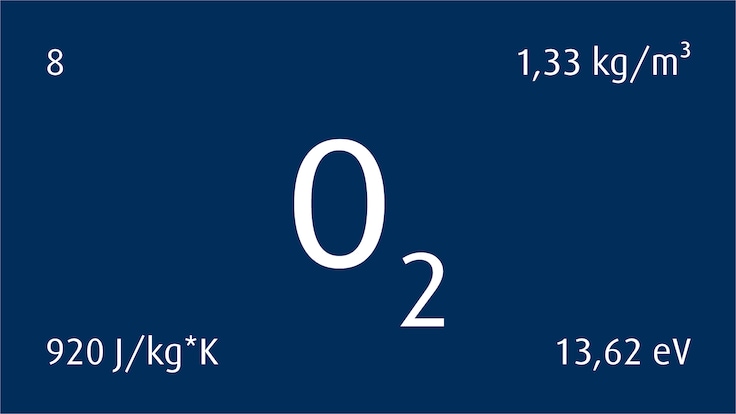

This gas dissociates and ionizes in the arc, immediately oxidizing any hot or molten metallic surfaces. Due to this high reactivity, welders should consider whether O2 is compatible with their process and material requirements, and how much of this reactive gas they need to add to their blend. Our products have between 0.03% and 12% O2 content.

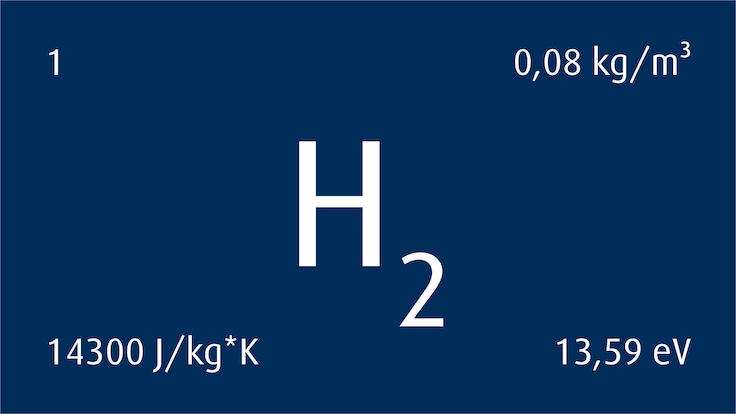

This is an oxygen-reducing agent. Once dissociated in the arc zone or on hot metallic surfaces, it can bind the available oxygen and thus avoid metal oxidation. H2 is also an excellent heat transfer agent. However, these advantages can only be leveraged with certain alloys like austenitic stainless steels, since many other alloys are prone to embrittlement or porosity in the presence of H2.

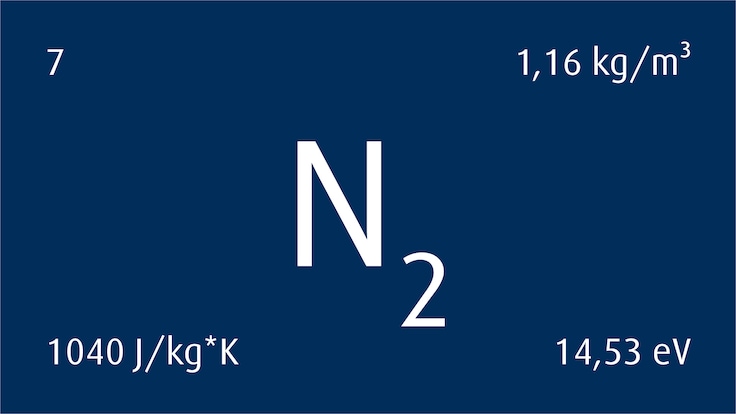

An N2 component in gas blends has low chemical reactivity. However, it is rarely used in welding mixes since it can cause porosity or embrittlement via intermetallic phases in many alloys. But its alloying effect makes it an attractive addition for certain austenitic or duplex stainless steels welding processes, where it can improve corrosion resistance of the joint.

| What Does the Welding Gas Do? | How Does this Benefit the Welding Result? | |

| Shields the arc and the molten pool against ambient air contamination | Obtain the desired metallurgical and mechanical integrity | |

| Influences arc ignition, discharge and stability | Help to create reproducible welds of stable quality with lower defect rates | |

| Controls electrochemical reactions and heat distribution at the cathode and anode | Lower welding fume emissions from the overheated wire electrode; improve weld surface and wetting on components | |

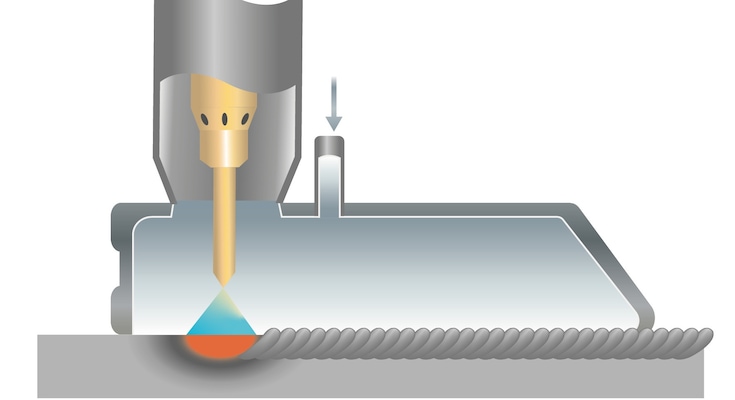

| Influences heat transfer from arc to molten pool and component | Improve control over heat input, avoid overheating and enable higher welding speeds | |

| Controls metal oxidation resulting from O2 and CO2 content | Less oxides, less silicates on weld surface and reduced burn-off of valuable alloying elements from filler | |

| Reduces oxidation with H2 | Enhance corrosion resistance in stainless steel welding and root backing | |

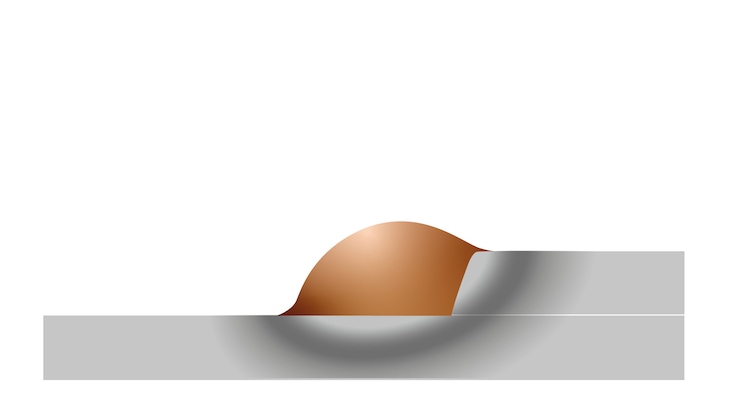

| Influences molten metal viscosity for droplet detachment and wetting behavior | Reduce spatter; improve joint performance under dynamic load; eliminate undercuts | |

| Stabilizes austenite phase through gas metallurgy, adding N2 to the blend | Engineer austenite/ferrite ratio for better corrosion resistance of duplex steel welds | |

| Reduces heat input to molten wire tip with lower CO2 content | Can reduce welding fume emissions from the arc |

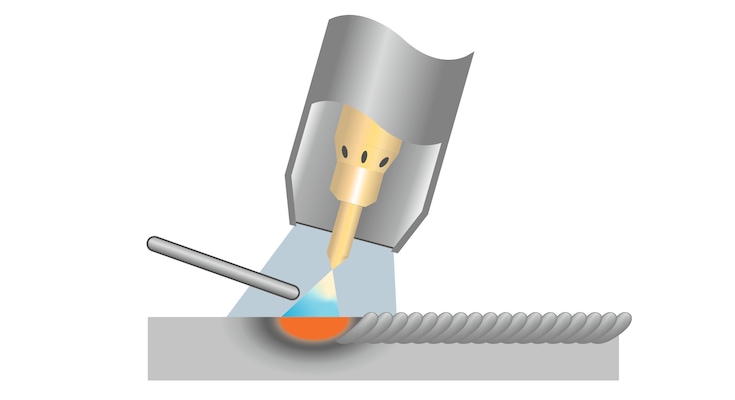

The addition of chemically active components affects the reactivity of the welding gas, affecting not only the metallurgical outcome but also the arc behavior. Industry best practice is generally guided by standards like ISO 14175 or its national versions, typically grouping welding gases by their chemical reactivity.

Added to all this material and process diversity is the challenge of job-specific standard requirements. Often, welding is just one fabrication step in a comprehensive metal fabrication value chain and many of the steps are regulated by industry standards.

In addition, every enterprise sets its own criteria for success. Those criteria can vary over time with progress being driven by ever-escalating competitive pressures and new metal fabrication trends such as:

As a leading gas partner to welding companies, we offer a comprehensive welding gases portfolio that can be adapted to support your individual needs. Our gases and mixes are aligned with local regulations and industry preferences, but always reflect our solid understanding of gas and arc physics. Please contact your local Linde representative to see what gases and blends are available in your area.

We offer a wide choice of supply modes to match individual consumption requirements. These start with small, compressed gas cylinders such as those used by craftspeople, extending all the way to on-site, stationary liquid bulk Ar or CO2 tanks, enabling large industrial metal fabrication sites to mix their blends on site. Across all supply modes, we deliver the same consistently high quality standards - whether that be for purity or moisture content in the case of gases or for mixing accuracy in the case of multicomponent blends. In fact, our welding gases usually exceed the minimum requirements specified in international standards like ISO 14175 and its national variants. We can also help with dedicated products and quality certificates if you require even higher purities for demanding welding tasks or if you work with reactive materials.

Our welding gases portfolio is marked under different local brands worldwide, including:

CORGON®, CRONIGON®, VARIGON®, ALUGON®, FORMIER®, MIGMIX GOLDTM, STARGOLDTM, STARGONTM, ARGOSHIELD®, SPECSHIELD® and STAINSHIELD®. Contact your local Linde representative to check availability in your region.

Discover how our tailored GMAW (MAG/MIG) welding gases and gas mixes can help you meet your job expectations

Explore how our gases and innovative blends can help you increase process flexibility and arc stability in FCAW/MCAW operations

Dive into our shielding gases for TIG/plasma welding to combine versatility with higher quality and process stability

See how root and shielding trail gases can protect your weldment against oxidation for cleaner results

Talk to our experts to explore how you can benefit from our expertise in more "exotic" processes such as stud welding and arc brazing