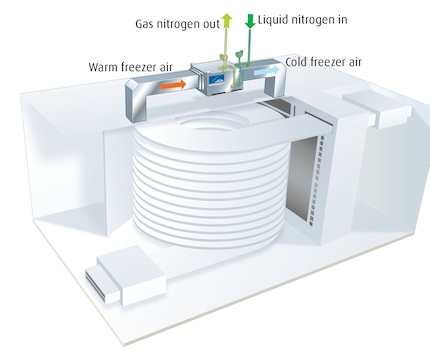

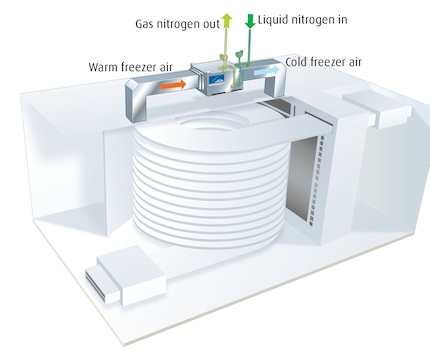

Boost your freezer performance with our compact, efficient NITROBOOST models tailored to both blast/shock freezers and spiral/tunnel designs

Time constraints mean more and more people are turning to high-quality convenience foods such as frozen snacks, cold cuts and ready-made meals. In fact, experts predict that the global frozen food market will reach USD 373.8 billion by 2028.

Manufacturers of prepared and frozen foods are racing to keep up with this growth while meeting increasingly strict food hygiene standards. Many are keen to scale up capacity and reach a new, wider customer base through innovative or improved products. Just as importantly, they want to do this without scrapping existing investments, for instance in mechanical freezers, or locking up capital in costly new facilities.

Here at Linde, we are at the forefront of cryogenic research into ways of helping you to balance these conflicting challenges. Leveraging the cryogenic power of liquid nitrogen (LIN) and carbon dioxide (LIC), our cryogenic innovations give you fast, flexible cooling and freezing performance. Many of our solutions can be integrated into existing production lines, also complementing existing installations on space-constrained footprints by delivering supplemental freezing power on demand.

Read on to discover how we are innovating the cryogenic chilling and freezing space ...

Boost your freezer performance with our compact, efficient NITROBOOST models tailored to both blast/shock freezers and spiral/tunnel designs

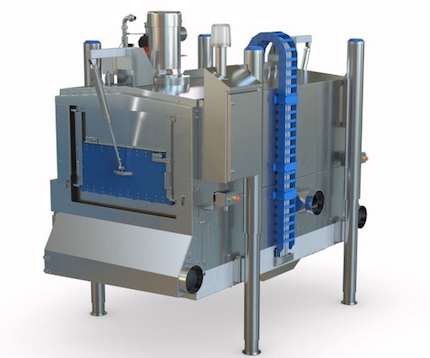

Achieve ideal crust freezing result with our just-in-time rapid crust freezer – a game-changer for high-capacity slicing lines

Coming soon...

Maintain consistently uniform temperature with blended products by injecting cryogens directly into the mixer from the bottom