NITROBOOST Add-on Refrigeration Technology

Boost Your Freezer Performance on Demand

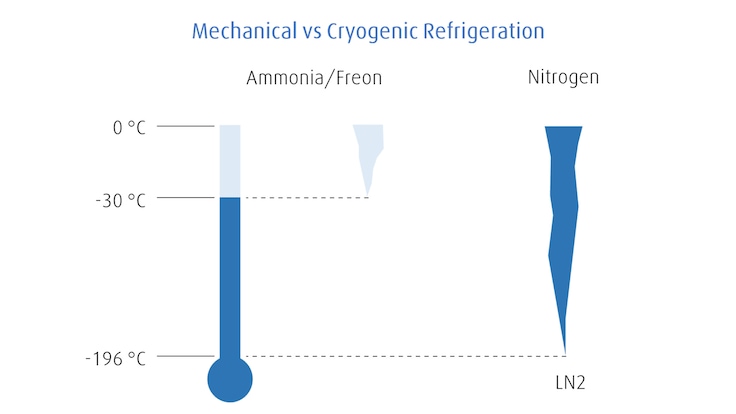

Food manufacturers often rely on ammonia or Freon refrigeration systems that struggle to keep up when production demands change. Blast freezers, for instance, may fail to reach target temperatures quickly, and spiral freezers may struggle to maintain consistent temperatures during production cycles.

These inefficiencies can compromise productivity, reduce product quality and lead to costly disruptions. Upgrading or replacing these freezers or mechanical refrigeration systems is expensive and time-consuming, adding further strain to production schedules.

Harness the Power of Liquid Nitrogen

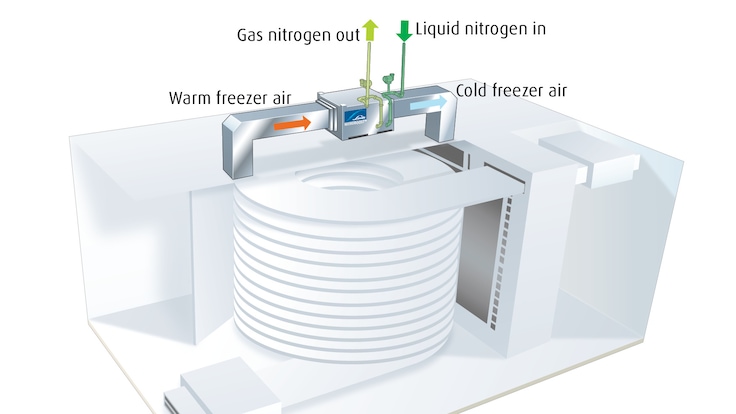

Linde’s NITROBOOSTTM technology offers an innovative and cost-effective solution by using indirect cooling of air inside the mechanical freezer with liquid nitrogen (LIN) heat exchangers without ever releasing the nitrogen inside the freezer. Designed for seamless integration with existing freezers, NITROBOOST boosts refrigeration capacity on demand to ensure efficient, reliable performance without costly overhauls.

A

cryogenic fluid, LIN is significantly colder than traditional industrial

refrigerants, enabling rapid and efficient heat removal on a compact footprint.

The LIN heat exchanger coils are up to 75% smaller than ammonia-based

evaporator coils. This compact design allows NITRBOOST systems to easily

integrate on top of or on the side of existing freezers.

NITROBOOST

is suited to most frozen products, including baked goods and cooked vegetables.

It is particularly beneficial for meat and poultry.

Temperature Fix for Spiral, Tunnel and Blast Freezers

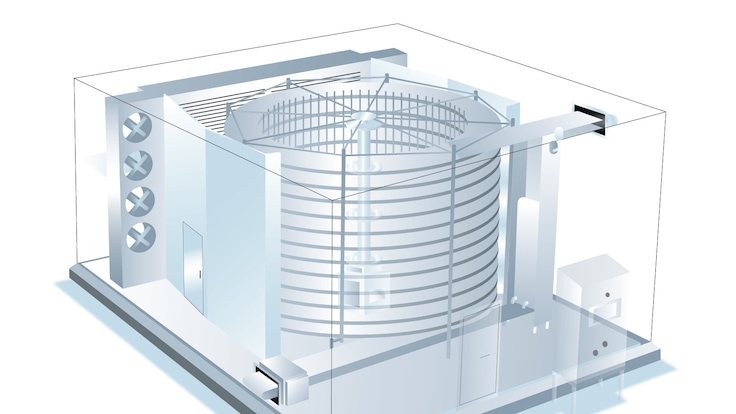

NITROBOOSTTM comes in two different models to suit different types of freezers.

NITROBOOST ST is the solution of choice for spiral and tunnel freezers. It gives operators the supplemental capacity they need to maintain target operating temperatures.

Achieve target temperature with NITROBOOST ST.

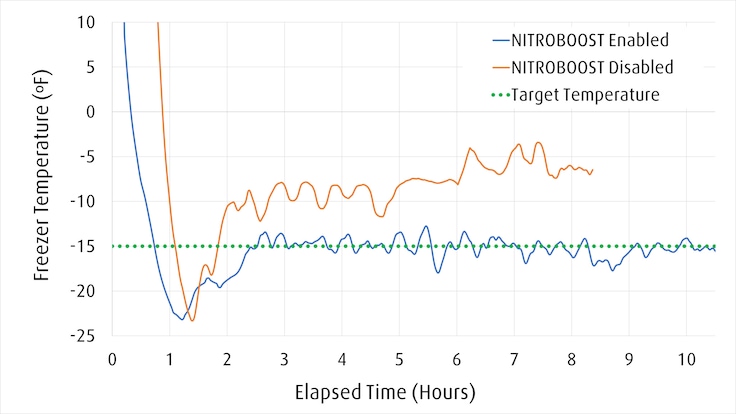

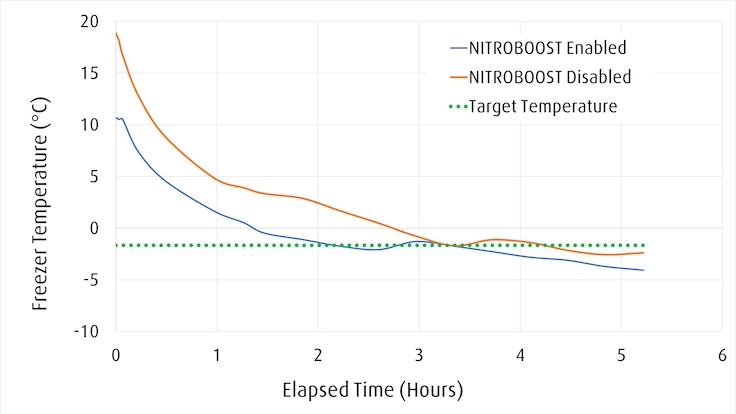

The NITROBOOST™ BL was designed specifically to enable blast and shock freezers to reach their target operating temperatures more quickly.

Faster cool down with NITROBOOST BL.

Improves Productivity, Profitability and Quality

Greater capacity Boost your production rates by up to 30%

Cost efficiency Lower your capital investment relative to mechanical upgrades

Easy retrofits Benefit from a compact design that requires no extra floor space

Enhanced quality Improve yield and reduce rework through precise temperature control

Safe operation Install a self-contained system that keeps nitrogen safely within the coils

NITROBOOST Technology in Action

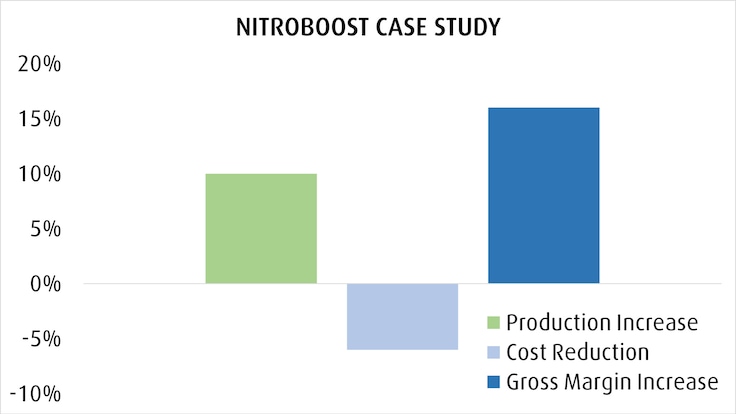

A large manufacturer increased profitability at a fraction of the cost required for alternative methods. The NITROBOOSTTM system was used to debottleneck freezing operations, increasing utilization of the existing spiral freezer without requiring capital expenditure. This unlocked profitability gains by reducing fixed and labor costs per unit while driving higher gross margins.

Product type Chicken nuggets

Freezer type Spiral

Average production rate 5000 lb/hr (2267 kg/hr)

Capacity increase with NITROBOOST 10%

Product inlet temp 140°F (60°C)

Desired product outlet temp 45°F (7°C)

Please note that the values in the above table are based on an individual, real customer study. A detailed analysis is required for different applications and production setups.Please contact your local Linde representative for advice on your particular requirements.