Dive into our shielding gases for TIG/plasma welding to combine versatility with higher quality and process stability

While carbon steels have many desirable characteristics, corrosion resistance is not one of them! All it takes is a little moisture or a salty atmosphere for the steel to start rusting. Stainless steels, however, are more resistant to corrosive attacks. These steels contain at least 12% chromium - much more than a low-alloyed carbon steel. Reacting with the oxygen present in air, this chromium forms a protective, passive layer of chromium oxide on the steel's surface.

The chromium content also has a significant influence on the microstructure and weldability of the material. In fact, other alloying elements such as nickel, molybdenum, titanium, copper and manganese are often added to tweak the microstructure and corrosion resistance in a specific direction. This is where designations like "austenitic", "ferritic" or "martensitic" come into play. The alloying elements complementing the chromium combine to impact the lattice structure, the properties and - by extension - the welding behavior.

It makes sense, therefore, that the process gases required for gas metal arc welding (GMAW) or metal active gas (MAG) welding of stainless steels differ from those suited to carbon steels, particularly when using solid filler wires or metal-cored wires. Typically, the amount of active components such as carbon dioxide (CO2) or oxygen (O2) in the gas blend is reduced to between 1 and 3% to avoid excessive oxidation that would otherwise impair corrosion resistance. A low level of CO2 also limits the pick-up of carbon from the welding gas to the weld metal, which could be problematic.

In the case of flux-cored wires, however, carbon steel welding gases are typically used, as the slag they form during welding protects the (weld) metal from detrimental effects like carbon pick-up and oxidation.

Highlights

Highlights

Highlights

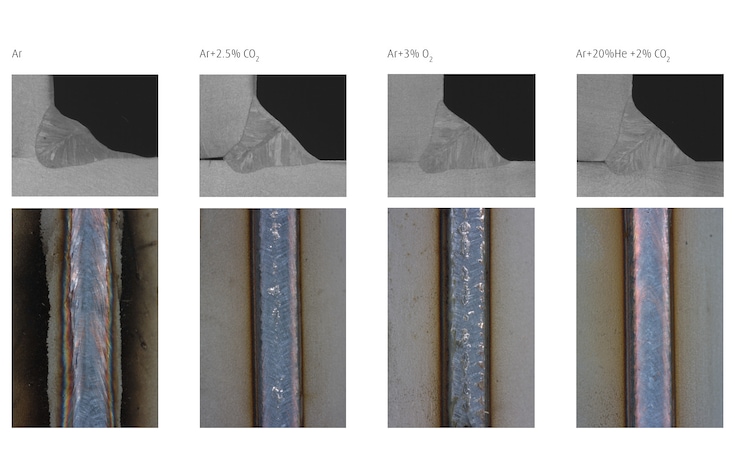

The photos below show the oxidation levels and general surface appearance of stainless steel fillet welds using different gases or blends based on the GMAW technique. (Pure argon is displayed for comparative illustration purposes and is not recommended for use.)

As a leading and trusted gas supplier to welding companies, we offer a broad portfolio to support individual needs and success factors. This portfolio spans two different lines so you can fine-tune your GMAW/MAG stainless steel welding operations and achieve your specific goals.

The table below lists the main features and benefits of our two product lines for GMAW/MAG welding of stainless steels.

| COMPETENCE LINETM | PERFORMANCE LINETM | |||

| Benefits to you | Enables all welding applications to meet industry standards | Higher welding performance, especially with advanced materials and arc processes | ||

| Typical gas blends |

|

|

||

| Examples of products available in certain regions |

|

|

Our welding gases portfolio is marked under different local brands worldwide, including: CORGON®, CRONIGON®, VARIGON®, ALUGON®, FORMIER®, MIGMIX GOLDTM, STARGOLDTM, STARGONTM, ARGOSHIELD®, SPECSHIELD® and STAINSHIELD®. Contact your local Linde representative to check availability in your region.

Dive into our shielding gases for TIG/plasma welding to combine versatility with higher quality and process stability

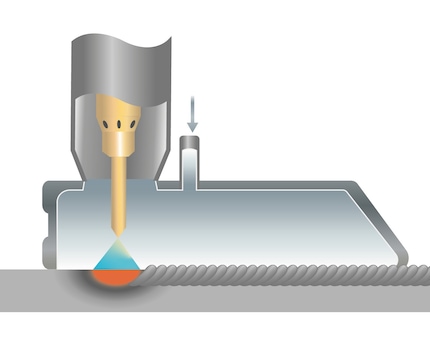

See how root and shielding trail gases can protect your heat-affected zone against oxidation for cleaner welds