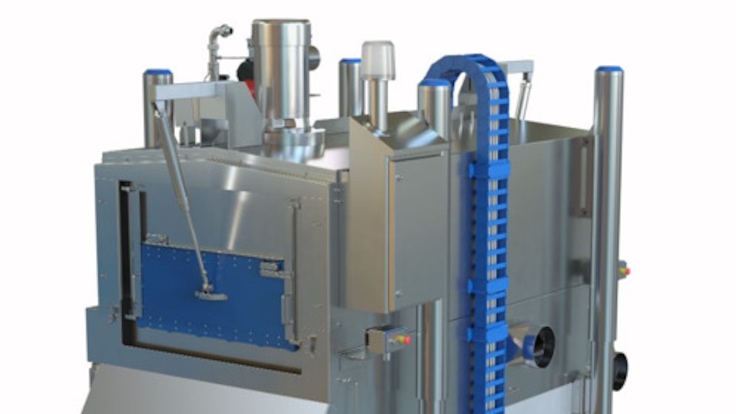

CRYOLINE RC Rapid Crust Freezer

Just-In-Time In-Line Crust Freezer

Addressing Today's Food Portioning Challenges

Consistent product portioning using methods such as slicing is a challenge for many food manufacturers. Crust freezing is commonly used to accelerate product portioning. With central crust freezers, however, the logs must be manually transferred to multiple slicers and this often presents consistency issues. As a result, central freezers frequently compromise production line efficiency and even profitability as mis-shaped cuts and give-aways result in product loss.

Here at Linde, we developed a innovative answer to these crust freezing yield and quality challenges - our CRYOLINE RC individual crust freezing solution. CRYOLINE RC is a semi-batch crust freezer specially designed for freezing the surface of larger pieces of food products prior to portioning using methods such as slicing or dicing.

How Does It Work?

CRYOLINE RC employs an innovative, patent-pending technology to rapidly crust freeze product surfaces through high-velocity gas flows combined with liquid nitrogen. This advanced approach ensures efficient heat transfer and uniform freezing, preserving product integrity and quality.

Seamlessly positioned before each slicer, the system supports just-in-time operations and reduces manual handling by integrating smoothly with upstream and downstream processes. It is ideally suited for pre-cut deli meats such as ham, sausage and cooked meats, as well as portioned whole cuts like pre-cut steaks and plant-based foods.

Benefits at a Glance

Proper crust freezing helps to preserve product quality by reducing the risk of tears, crumbling and miscuts, while also increasing portioning accuracy due to the firmer product structure. This means you can look forward to higher yield and reduced downtime.

The innovative design of CRYOLINE RC means you can also enjoy the following benefits:

- Space savings: Rapid heat transfer on small footprint.

- Time savings: Heat transfer rate of general-purpose tunnel freezers accelerated by up to 1000%.

- Resource efficiency: Optimized cryogen use.

- Cost savings: Semi-batch product handling, synchronized with slicer operation.

- Optimized production flows: Seamless integration with upstream and downstream processes.

- Greater food safety: Reduced manual product handling.

- Ease of cleaning: Hygienic design.