- More tolerant parameter window to obtain required penetration, especially in out-of-position welding

- Robust arc stability on unclean, oxidized or coated surfaces

- Increased heat transfer and input with lower risk of porosity

The term "carbon steels" collectively refers to various unalloyed and low-alloyed steels, including fine-grained structural steels, mild steels, high-strength steels and coated steels. All of these have carbon as the main alloying element in iron, and do not classify as stainless steels.

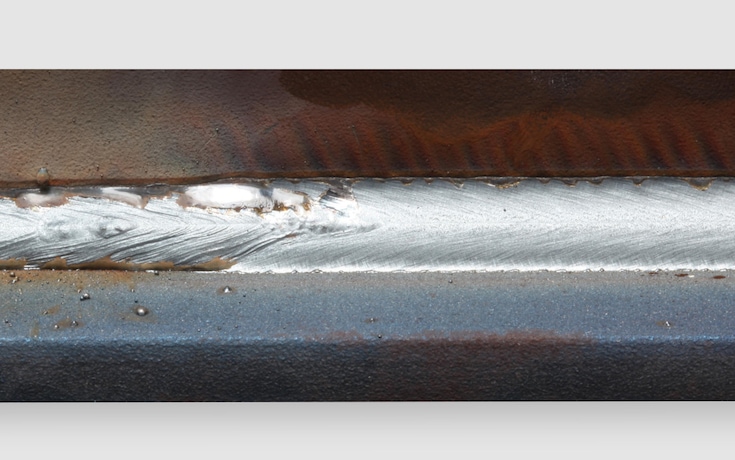

If you decide to use gas metal arc welding (GMAW) / metal active gas (MAG) welding with solid fillers on these materials, you will require an oxidizing blend. Inert gases will not be an option as pure argon or argon/helium mixes will not create a stable welding arc. High-quality solid fillers available on the market are typically certified for use in combination with specific oxidizing gases.

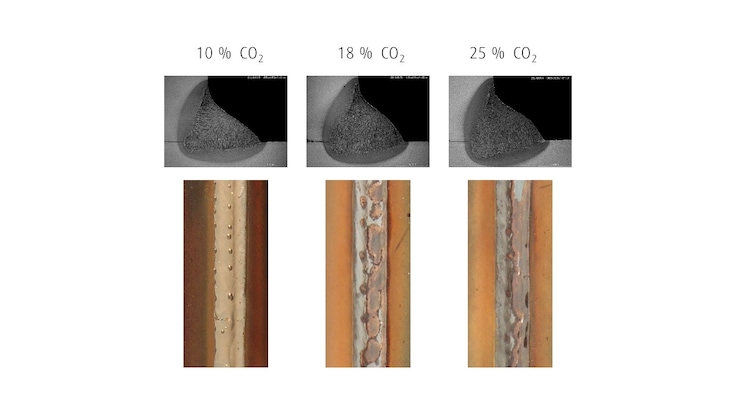

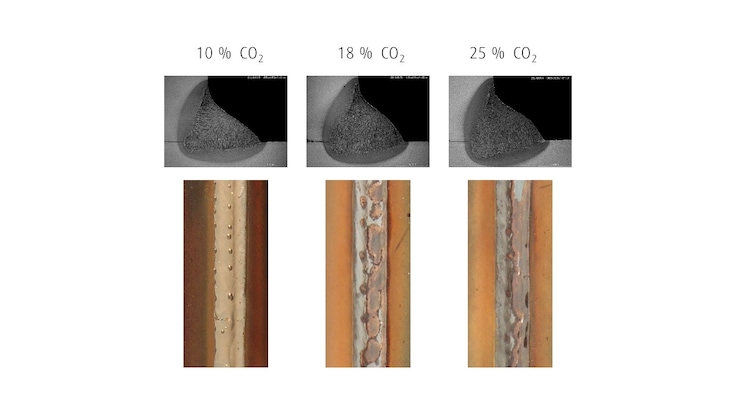

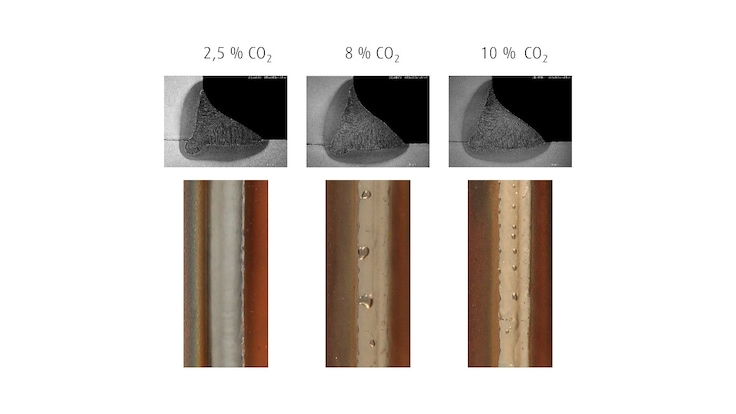

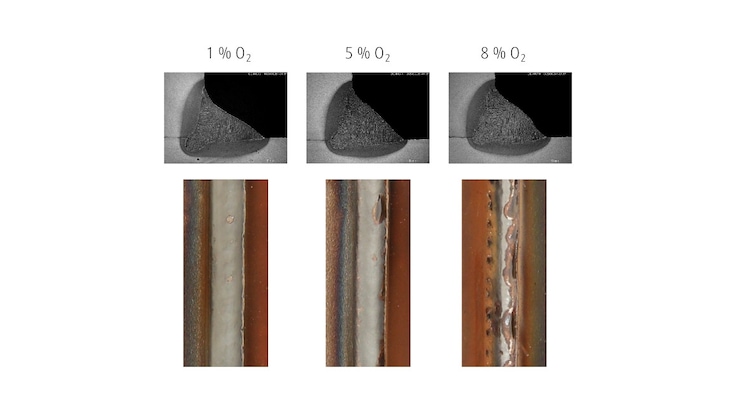

Due to their compelling quality and economy advantages, argon-based gas blends with carbon dioxide (CO2) and/or oxygen (O2) as the active components are now much more widely used than pure CO2 for GMAW/MAG welding of carbon steels. But as the technology evolves, the amount of active gas added to argon (Ar) as the base gas is continuously being re-evaluated. The mix ratio plays a decisive role in the welding process itself and the weld result. Below are just some of the variables that influence the choice of welding gas:

The general rule of thumb when deciding on the active gas, CO2 or O2 content is "as little as possible and as much as necessary".

In high-performance applications where the CO2 content has been reduced for the reasons mentioned, the addition of helium (He) can compensate for the loss of heat transfer to the component resulting from the lack of CO2. Replacing 15-35% of Ar with He in GMAW mixes of lower reactivity enables higher welding speeds with the desired wetting and penetration profiles.

With the growing adoption of mechanization, automation and pulse arc techniques, gas blends with a reduced CO2 or O2 content are becoming increasingly popular.

Recent studies have contributed to this trend, demonstrating how welding gases with lower CO2 content can also reduce welding fume emission rates directly at the source - in the GMAW arc. Several OSH institutions reference, in the hierarchy of controls, optimization of welding gas composition as a substitution type measure to complement other existing fume control measures.

As a leading and trusted gas supplier to welding companies, we offer a comprehensive portfolio to support individual needs and success factors. This portfolio spans three different lines so you can fine-tune your GMAW/MAG carbon steel welding operations and achieve your specific goals.

The table below lists the main features and benefits of our three product lines.

| COMPETENCE LINETM | PERFORMANCE LINETM | PREVENTION LINETM | ||||

| Benefits to you | Enables welding applications to meet industry standards | Higher welding performance, especially with advanced materials and arc processes | Can reduce welding fume emissions at the source - in the GMAW arc | |||

| Typical gas blends |

|

|

|

|||

| Examples of products available in certain regions |

|

|

|

As an international company, we comply with local regulations and market requirements. Please contact your local Linde representative to see what gases and blends are available in your area.