Enhance process stability, precision and controllability in annealing, hardening, carburizing, nitriding, brazing and more

Gases, along with temperature and time, play a key role in ensuring the stability and controllability of heat treatment processes. Building on the experience we have gained in the successful delivery of countless heat treatment projects worldwide, we can help you fine-tune the gas atmosphere in contact with your workpiece - whether you operate a batch, continuous or vacuum furnace. We complement our comprehensive range of process gases with gas control, injection and analysis technologies plus service, support and advice to help you achieve the best outcomes. Our expertise spans controlled furnace atmospheres, vacuum and sub-zero processes as well as powder metallurgy.

Our core competencies in heat treatment include:

Enhance process stability, precision and controllability in annealing, hardening, carburizing, nitriding, brazing and more

Process gases in the purity, flow, pressure and volume your furnace needs for reliable operation

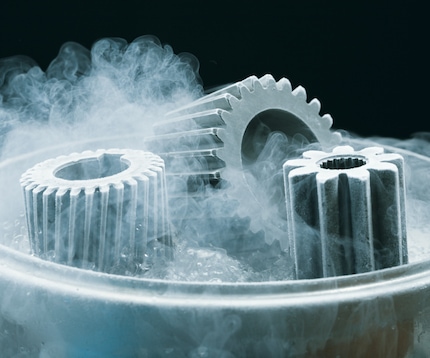

Improve material properties and extend the lifetime of heat-treated parts with our cryogenic treatments

Check out our gases and supply solutions for gas-intensive powder processes such as atomization, sintering and hot isostatic pressing

Click to explore the benefits of a single source for all your gas installation, supply, service and support needs in heat treatment