Our expert team would be happy to advise you on your gas-related concrete curing needs

Carbon Dioxide for Concrete Curing

Lower Carbon Footprint with CO2 for Concrete Curing

Concrete Offering the Same Performance with a Smaller Carbon Footprint

Indispensable for most construction projects, concrete nonetheless has a high carbon footprint. 50 percent of the limestone fed into a concrete kiln is typically released as carbon dioxide (CO2) emissions.

Carbon removal technologies work by injecting captured (recycled) CO2 into concrete during mixing. Once injected, the CO2 mineralizes and becomes calcium carbonate, which is permanently trapped in the concrete. This mineralization process improves the compressive strength of the concrete, which enables concrete producers to optimize their mix designs while delivering the required strength. The end result is the same reliable concrete, with a reduced carbon footprint.

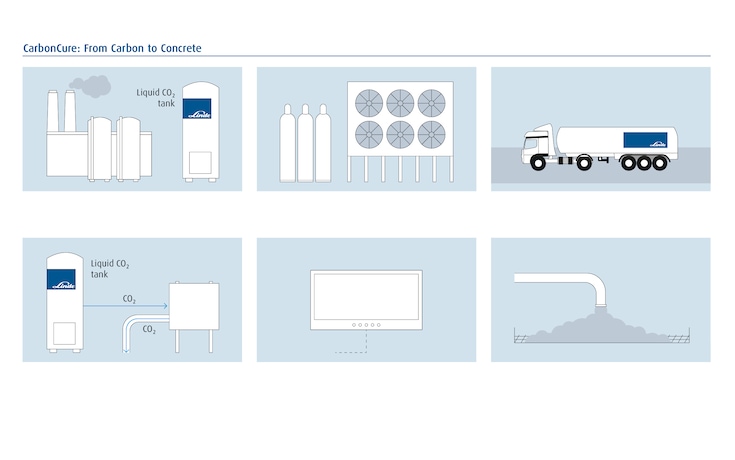

We have teamed up with various experts in cement carbonation curing to complement their innovative carbon dioxide removal technologies with our market-leading CO2 supply and control equipment for enhanced curing results. Our liquid carbon dioxide supply and control solutions are tailored specifically to the concrete curing processes developed by companies such as CarbonCure and Carboclave. Our Carboclave alliance focuses on the enhanced manufacturing of prefab cement products, whereas our CarbonCure engagement spans precast, ready-mix and masonry products.

Benefits of CarbonCure & Linde Alliance

- Strategic alliance between Linde and CarbonCure Technologies for optimum interplay and project outcomes

- CO2 supply solution tailored specifically to the CarbonCure technology package including dedicated connection kit

- Reduction in cement content (by 3-6% on average) - with no impact on quality or performance

- Bolt-on solution for deployment flexibility

- Lower costs

- Greener concrete with smaller carbon footprint

Facts and Figures: CarbonCure Concrete

- 15.5 million cubic yards (11.9 million cubic meters) of concrete poured to date

- 500 systems licensed to concrete plants around the world

- 2 million truckloads of concrete made with CarbonCure delivered to date

- Nearly 1 million truckloads delivered in a year

- 100,000 truckloads delivered in a month

- 132,000 metric tons of CO2 saved to date - equal to the annual emissions from 28,750 cars

Benefits of Carboclave & Linde Alliance

- Strategic alliance between Linde and Carboclave for optimum interplay and project outcomes

- CO2 supply solution tailored specifically to the Carboclave technology, available as retrofit (minor process changes only) or built-to-spec solution

- High-performance premium product

- Net negative carbon footprint operation

- No energy or water required for curing

- Inventory cost reduction (less cure time)

- Production and material cost savings

- Turnkey delivery with fully automated operation and safety protocols

Facts and Figures: One Carboclave Concrete Block

- 50% reduction in carbon footprint compared with conventional blocks

- Up to 25% cement reduction

- Up to 250 g CO2 sequestered

- More than 500 g reinforcing nano-CaCO3

- Higher strength than commercial benchmark

- Improved mechanical and durability performance